A Look Inside the Labor-Intensive Process of Making a Tiffany-Style Lamp

What do Tiffany lamps have in common with Kleenex?

A brand name so mighty, it’s become an umbrella term.

Of course, Kleenex is still manufacturing tissues, whereas authentic lamps from Louis Comfort Tiffany’s New York studio were produced between 1890 and 1930.

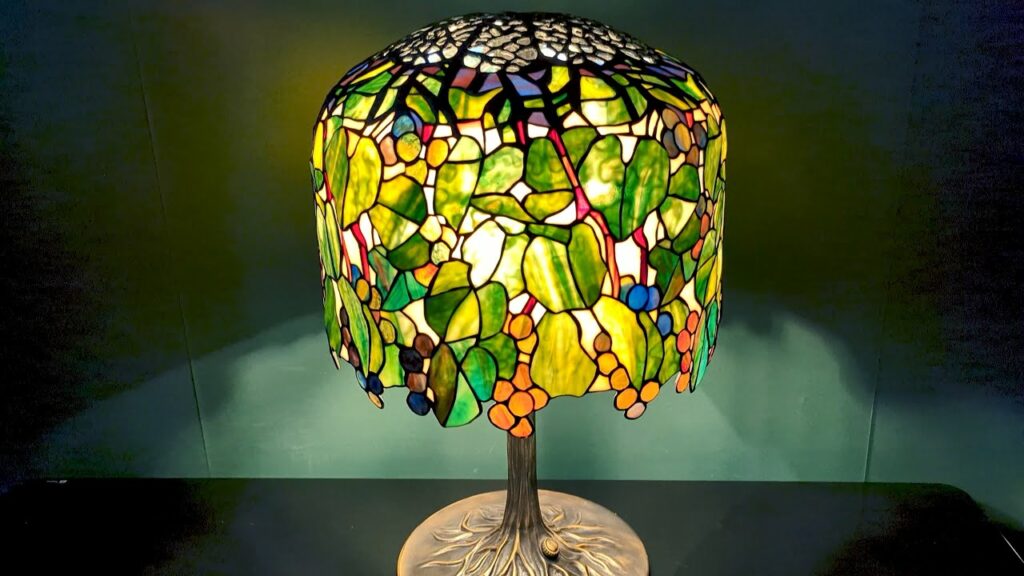

Handcrafted of coiled bronze wire and many pieces of blown favrile glass arranged in intricate natural motifs, bonafide Tiffany lamps can fetch prices of over a million dollars.

The “Tiffany lamps” for sale on Wayfair?

Not the genuine article.

Still, if the one on your end table brings you pleasure, who are we to get snippy about it?

There’s plenty of that attitude to be found in the YouTube comments for the above process video …

To be clear, what you’re seeing is the process by which an affordable colored glass lampshade in the style of Tiffany comes together at an overseas factory.

The quality may be lacking, but it’s still a pretty labor-intensive proposition.

First, the pieces are cut by hand or using blades mounted on metal arms. Their shapes and number are predetermined by a pattern…again in the style of Tiffany.

You won’t find the speckled confetti glass or golden hued glass with a translucent amber sheen that are defining features of the real McCoy here…

Once the pieces have been cut and sorted, their edges are wrapped in copper foil tape. (In Tiffany’s day this would have involved hand cutting strips of copper, then smearing them with beeswax to help them to adhere to the glass.)

The wrapped pieces are then laid out in a mold according to the pattern and soldered together.

The bottom edge is reinforced, and the shade is fitted onto a lamp base.

If you’re a museum curator, a connoisseur of the genuine article or a glazier, we don’t fault you for getting a bit salty.

(Our favorite comment: Oh the humanity. I used to be a glazier. I couldn’t finish watching the video. The way they cut the glass dry and slide it around without felt on the table makes me cringe. You can hear the crinkling sound of glass particles under it when it’s being slid around. The smallest contoured cuts and breaks are so rough they’re practically gnawed. If clear glass was handled this way every window would have deep scratches and would probably self destruct from thermal cycling or a strong breeze.)

If you’re susceptible to ASMR, enjoy your tingles – all those crinkling sounds of glass particles!

If you’re someone who’s insatiably curious as to how ordinary things are made, we hope you’ll consider the twelve minutes of this Process Discovery video time well spent, and no less interesting than their non-narrative peeks into the manufacture of bubble mailers, snow globes and swim goggles …

We leave you with a brief tour of the “real thing”, courtesy of the New York Historical Society:

Related Content

– Ayun Halliday is the Chief Primatologist of the East Village Inky zine and author, most recently, of Creative, Not Famous: The Small Potato Manifesto and Creative, Not Famous Activity Book. Follow her @AyunHalliday.